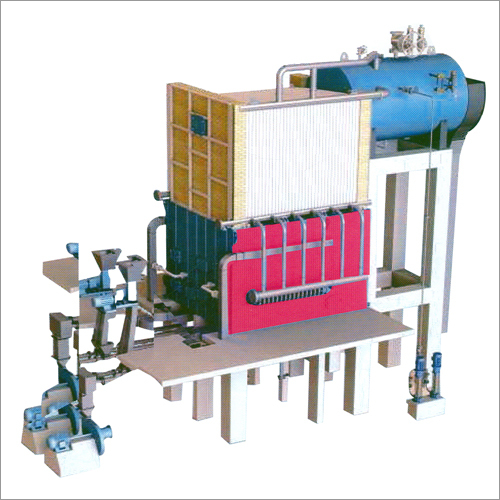

Process Heating System

Product Details:

- Style Horizontal

- Condition New

- Voltage 120-240 Volt (v)

- Fuel Type Coal- Fired

- Material Mild Steel

- Product Type Process Heating System

- Click to View more

Process Heating System Price And Quantity

- 155000 INR/Unit

- 1 Unit

Process Heating System Product Specifications

- 120-240 Volt (v)

- New

- Process Heating System

- Horizontal

- Mild Steel

- Coal- Fired

Process Heating System Trade Information

- Cash in Advance (CID), Cheque

- 7-8 Unit Per Month

- 30 Days

- Process Heating System

- All India

Product Description

Backed by our dedicated team and state of the art manufacturing facility, we are affianced in offering the best quality Process Heating System to our valued customers. Designed in adherence with the internationally accepted standards we utilize the best quality raw material and advanced technologies for manufacturing this heating system. Known for its high efficiency and optimum performance our heating system is widely used in providing heating solutions for various domestic and commercial establishments. We offer this Process Heating System at competitive price to the clients.

Features:

- Compact design

- Less power consumption

- Easy installation

Further Details:

Process Heating System

Technical Specifications:

| Description | Unit | CPED-40 | CPED-60 | CPED-80 | CPED-100 | CPED-120 | CPED-140 | CPED-160 |

| Capacity (kg/hr F and A 100 deg C) | Kg / hr | 4000 | 6000 | 8000 | 10000 | 12000 | 14000 | 16000 |

| Design pressure (SVLOP) | Kg / cm 2g | 10.54/17.5 | ||||||

| Fuel | | Husk/Indian Coal/ Indonesian coal / Lignite | ||||||

| Fuel feeding system | | Auto - Underbed / Overbed | ||||||

| Combustion system | | Fluidised Bed Combustion | ||||||

| Furnace compartments | | 1 2 | ||||||

| Efficiency (Under bed / Over bed) | % | As Per BS 845 Part-1 NCV Basis | ||||||

| Husk | % | 85 | ||||||

| Indian coal | % | 86 | ||||||

| Indonesian coal | % | 86.5 | ||||||

| Lignite | % | 84.5 | ||||||

| Fuel consumption | | Underbed / Overbed | ||||||

| Husk (NCV-2900) | Kg/hr | 657 | 876 | 1059 | 1314 | 1752 | 2190 | 2628 |

| Indian coal (NCV-5500) | Kg/hr | 342 | 456 | 570 | 684 | 912 | 1140 | 1368 |

| Indonesian coal (NCV-5800) | Kg/hr | 322 | 429 | 536 | 643 | 858 | 1073 | 1287 |

| Lignite (NCV-2800) | Kg/hr | 684 | 912 | 1141 | 1369 | 1825 | 2282 | 2738 |

| Connected load (10.54/17.5) | With APH and MDC | |||||||

| Under Bed firing | | 38/40 | 48/50 | 69/73 | 90/92 | 109/119 | 135/139 | 171/178 |

| Over Bed firing | | 36/38 | 39/49 | 58/62 | 75/77 | 90/100 | 114/118 | 149/157 |

| Dimensions | | |||||||

| A | mm | 9841 | 10430 | 10651 | 11130 | 10786 | 13318 | 10754 |

| B | mm | 4600 | 4829 | 5449 | 5300 | 5500 | 7249 | 7369 |

| C | mm | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 |

| D | mm | 6515 | 6370 | 7040 | 6905 | 7295 | 7495 | 7505 |

| E | mm | 23000 | 24000 | 24400 | 25000 | 25000 | 27000 | 25063 |

| F | mm | 8220 | 8704 | 9654 | 9955 | 10675 | 12544 | 12804 |

| G | mm | 9040 | 9045 | 10084 | 10100 | 10870 | 10990 | 11000 |

| Chimney top diameter | mm | 600 | 700 | 800 | 900 | 1000 | 1100 | 1150 |

| Dry weight (10.54/17.5) | ||||||||

| Boiler shell | Tonne | 4.5/5.0 | 6.0/6.5 | 7.5/8.5 | 9.0/10.0 | 12.5/14.0 | 14.0/16.5 | 17.0/19.0 |

| Furnace | Tonne | 32.0 | 37.0 | 46.0 | 54.0 | 70.0 | 75.0 | 75.0 |

| Flooded weight (10.54/17.5) | | |||||||

| Boiler shell | Tonne | 10.0/10.5 | 12.0/12.5 | 16.0/17.0 | 19.0/20.0 | 26.0/27.5 | 29.5/32.0 | 34.5/36.5 |

| Furnace | Tonne | 33.0 | 38.0 | 47.5 | 55.5 | 72.0 | 77.0 | 77.0 |

FAQs of Process Heating System:

Q: What is the material used in the construction of the Process Heating System?

A: The Process Heating System is constructed using Mild Steel.Q: What type of fuel does the Process Heating System operate on?

A: The Process Heating System operates on coal as its fuel type.Q: What is the voltage range supported by the Process Heating System?

A: The Process Heating System supports a voltage range of 120-240 Volt (V).Q: What is the orientation design of the Process Heating System?

A: The Process Heating System has a horizontal orientation design.Q: Is the Process Heating System a new or refurbished product?

A: The Process Heating System is a new product.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM

Call Me Free

Call Me Free