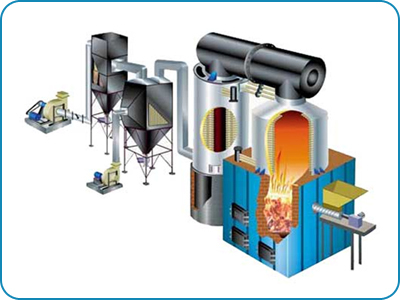

Vertical Four Pass FBC FIred Thermic Fluid Heater

Product Details:

- Type FBC FIred Thermic Fluid Heater

- Material Mild Steel

- Voltage 380 Volt (v)

- Power Source Electric

- Weight (kg) 3.4 to 48 Tonne

- Warranty 1 Year

- Click to View more

Vertical Four Pass FBC FIred Thermic Fluid Heater Price And Quantity

- 1 Unit

- 550000 INR/Unit

Vertical Four Pass FBC FIred Thermic Fluid Heater Product Specifications

- 1 Year

- 3.4 to 48 Tonne

- Mild Steel

- Electric

- FBC FIred Thermic Fluid Heater

- 380 Volt (v)

Vertical Four Pass FBC FIred Thermic Fluid Heater Trade Information

- Cash in Advance (CID), Cheque

- 7-8 Unit Per Month

- 30 Days

- All India

Product Description

Vertical Four Pass FBC Fired

Further Details

- The VFF-arrangement, vertical four pass F.B.C terminated thermic liquid/warm oil warmer is intended for greatest proficiency, utilizing an assortment of free stream powers including agro-waste powers and pummeled coal. It permits high process temperature.

- Thermic Fluid Heater.

- Tmperatures at low working weights.

Product Features:

- For fuel such as pulverized coal, rice husk ,sawdust, petcock,

- Option of grate/ fluidization bad or suspending burning bad.

- Simple operation in varied type of free flow fuel with maximum efficiency.

- Capacities: From 0.4 to 10.0 million kcal/hr

- Firing fuels: pulverized coal ,rice husk, sawdust, petcock

- Efficiency: Overall efficiency of 80 % (+/-2%) on NCV with APH.

| MODEL | UNIT | VFM-04 | VFM-06 | VFM-10 | VFM-15 | VFM-20 | VFM-25 |

| Heat Output | 1000 Kcal/ hr | 400 | 600 | 1000 | 1500 | 2000 | 2500 |

| Oil Flow Rate | M3/hr | 24 | 36 | 60 | 90 | 90 | 150 |

| Max. Outlet Temp. | *C | 280 | 280 | 280 | 280 | 280 | 280 |

| Temp. Rise In Heater | *C | 34 | 34 | 34 | 34 | 34 | 34 |

| Max. Fluid Pressure Heater Outlet | Kg/cm2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Efficiency |

| ||||||

| On Coal | % | 76+/-2 | 76+/-2 | 76+/-2 | 76+/-2 | 76+/-2 | 76+/-2 |

| Husk | % | 70+/-2 | 70+/-2 | 70+/-2 | 70+/-2 | 70+/-2 | 70+/-2 |

| On Petcock | % | 78+/-2 | 78+/-2 | 78+/-2 | 78+/-2 | 78+/-2 | 78+/-2 |

| Type of Fuel |

|

| Coal | Husk | petcock |

|

|

| Fuel consumption |

| ||||||

| Coal | Kg/hr | 120 | 175 | 290 | 435 | 580 | 750 |

| Wood | Kg/hr | 175 | 260 | 435 | 650 | 870 | 1085 |

| Petcock | Kg/hr | 60 | 90 | 150 | 225 | 300 | 375 |

| Electrical Load |

| ||||||

| Thermic Oil Pump | H.P. | 10 | 15 | 20 | 30 | 40 | 40 |

| F.d. Fan (Coal / wood) | H.P. | 2 | 3 | 5 | 7.5 | 10 | 12.5 |

| I.d. Fan | H.P. | 5 | 7.5 | 10 | 15 | 20 | 25 |

| F.d. Fan | H.P. | 5 | 7.5 | 10 | 15 | 20 | 25 |

| S.f.d Fan | H.P. | 1 | 1 | 1 | 2 | 2 | 3 |

| Fuel Feeder | H.P. | 1 | 1 | 1 | 2 | 2 | 2 |

| Total Ele Load | H.P. | 24 | 35 | 47 | 70.5 | 93 | 106.5 |

| Coil Hold up Cap. | Ltrs | 475 | 570 | 1250 | 2350 | 3150 | 3780 |

| Furnace Size |

| ||||||

| Length | M.M. | 1720 | 2040 | 2240 | 2590 | 2875 | 2875 |

| Width | M.M. | 1720 | 2040 | 2240 | 2590 | 2875 | 2875 |

| Height | M.M. | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 |

| Heat Exchanger Dim |

| ||||||

| Convective Coil | Dia | 1150 | 1270 | 1510 | 1800 | 2030 | 2420 |

| Height | 1790 | 2100 | 2860 | 3660 | 4210 | 4220 | |

| Radiant Coil | Dia | 2000 | 2000 | 2250 | 2600 | 2900 | 2900 |

| Height | 1500 | 1500 | 1900 | 2700 | 3150 | 3550 | |

| Oil Inlet Connection | M.M. | 80 | 80 | 100 | 125 | 150 | 150 |

| Oil Outlet Conne. | M.M. | 80 | 80 | 100 | 125 | 150 | 15 |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Mon-Sat 9.00 AM to 6.00 PM

Mon-Sat 9.00 AM to 6.00 PM